Hollywood, Fla.-based Memorial Healthcare System (MHS) was used to going it alone, but forging a partnership with clinical engineering services group ABM Healthcare proved to be a boon to operations. Below, Mike Ahmad, ACHE, vice president, business growth and imaging technology, ABM Healthcare, shares how the transition benefitted MHS and why HTM professionals should have a seat at the table when purchasing new equipment.

24×7 Magazine: How has Memorial Healthcare System’s HTM department evolved in the past few years? How do you expect it to evolve even more in the future?

Mike Ahmad: Prior to Memorial Healthcare System (MHS) partnering with ABM, each of the system’s six healthcare technology management departments operated independently—with six unique medical equipment management plans. The key objectives of the partnership were to boost collaboration and gain operational efficiencies through improved communication and standardization.

When the healthcare technology management program began in 2013, both ABM and Memorial Healthcare System faced the challenges of integrating six diverse biomedical departments into a singular HTM department under the leadership of information technology. Other challenges were standardizing operations, reducing costs and, most importantly, improving the service of managed medical equipment.

Early in the process, we established a HTM steering committee to focus on program implementation, identifying milestones and evaluating performance indicators. The mission of the steering committee was—and continues to be—identifying the key metrics used to measure the success of program implementation and ongoing program management. The group developed a five-year plan outlining manpower projection, equipment transitions, and key performance indicators to track successful service delivery.

ABM’s first objective was understanding the current state of the HTM program in relation to customer service expectations, equipment uptime, service levels, response times, service costs, total cost of ownership, and strategic planning. Once we had all that data, we started building a business plan to implement and deliver an internal service program at levels that exceeded those being delivered in the current model.

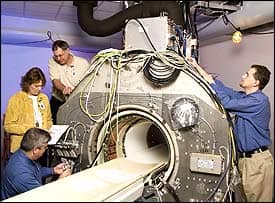

The clinical engineering department has evolved from a “break-fix” program to a true HTM program, which is involved in many aspects of the Healthcare Needs Assessment, including technology acquisition, project management for new construction and installations, as well as technology management of contracted services.

24×7: The HTM department at MHS has a history of performing well in Joint Commission surveys. What accounts for the team’s success?

Ahmad:Healthcare technology management programs will see continuous changes in healthcare in the next few years, and we need to be a proactive part of the change process. Service providers must hire the right technical and managerial expertise and position them as a key resource for proactively addressing these new healthcare challenges. The expertise that ABM brings to the table allows us to be an integral part in ensuring the compliance and success of every regulatory inspection.

24×7: Cost-savings is always a goal in HTM. What are some ways MHS’ HTM department keeps spending in check?

Ahmad: Healthcare technology management departments should focus on reducing costs while improving the quality of medical technology service. Most importantly, it is crucial that the healthcare technology management department secure a seat at the negotiation table when medical equipment is purchased. After all, the ability to influence a few key variables at the beginning of the lifecycle will pay tremendous returns over the life of the equipment.

Strategies for success are best negotiated before the vendor is selected and the equipment is purchased. These strategies include: equipment standardization; enabling healthcare institutions to leverage purchasing power; effective equipment needs assessment; eliminating the acquisition of underutilized technology; and, finally, negotiating extended warranties, advantageous service and business terms, and technical training for service engineers. For us, establishing a strategic plan with key service provides for the purchase and delivery of high-end imaging equipment glassware, as well as other “high-failure-rate” parts for critical equipment, improved equipment uptime and reduced costs by more than 50%.

24×7: Can you please discuss a time when MHS’ HTM department “saved the day” for another hospital department?

Ahmad: One Thursday morning, the health system’s chief nursing officer called for an emergency meeting to address the influx of patients overloading our largest facility’s emergency department Her mission was to transform an area that was currently being used for storage into a 15-bed patient overflow area by 7 a.m. Monday morning. She said, “I know I am asking you to move mountains, but we need to make this happen.” This was asked of us while we were in the middle of physically moving our entire HTM department to a new location.

With an “all-hands-on deck” approach, we brought in staff from the other HTM departments across the system, redeployed equipment from other resources, and installed a 15-bed, centrally monitored system that could communicate with the electronic health records. Within 72 hours, everything was operational.

24×7: Cybersecurity is a huge issue in HTM. What steps is the HTM department at MHS taking to thwart cyberattacks?

Ahmad:Medical device cybersecurity vulnerabilities and intrusions pose risks for every hospital and its reputation. Yes, there are significant benefits for healthcare delivery and organizational efficiency from the expanded use of Internet-enabled medical devices and electronic databases for clinical, financial, and administrative operations. But such technologies also increase our exposure to possible cybersecurity threats, which require hospitals to evaluate and manage new risks.

There is a need to balance protecting patient safety and promoting the development of innovative technologies and improved device performance. ABM, for instance, has created the following step-by-step process to ensure patient safety and patient information safety.

- Maintaining a repository of Manufacturer Disclosure Statements for Medical Device Security, or MDS2

- Following strict procedures for onboarding, decommissing, and sanitizing medical devices

- Determining risk levels and suitable mitigation strategies

- Assessing the likelihood of threats and vulnerabilities