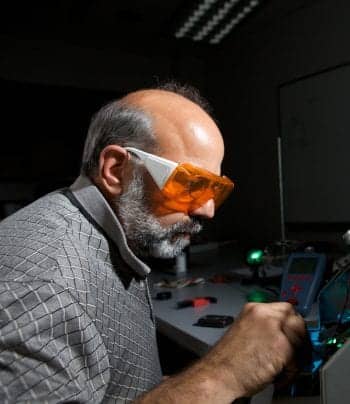

Joe Zainey, a BMET 3, works on the alignment of a medical laser.

In 1855, a smallpox epidemic prompted the city of Indianapolis to build a hospital. Four years later, City Hospital opened its doors. Today, more than a century later, the facility remains open, though it has undergone a few name changes. Currently managed by Wishard Health Services, in 2014 it will change its name once again to Eskenazi Health. But whatever the name, the mission has remained the same: to “advocate, care, teach, and serve, with special emphasis on the vulnerable populations of Marion County, Indiana.”

The current organization is comprised of a 339-bed hospital located in Indianapolis, 10 community health centers, and 21 community mental health sites and residential facilities. As stated in its mission, Wishard does not turn away patients who cannot pay. Roughly 40% of its payor mix is uninsured, and nearly half are Medicare/Medicaid patients. The hospital receives government funding, but its budgets are often very tight, sometimes requiring creativity on the part of employees.

The staff at Wishard take its mission seriously. The organization is active in the community through a variety of avenues, including health fairs and community clean-ups. “We extend our involvement with the population way beyond when they come in the door for medical care,” says Dan Dudley, CBET, director of medical engineering for Wishard Health Services.

Similarly, the biomed team extends itself outside the walls of its shop, creating a service organization designed to “advocate, care, teach, and serve” patients, customers, and the department itself. This has led to a new structure and fluid approach that creates a true sense of teamwork while inspiring individual responsibility.

Advocating BMET 3

Wishard’s medical engineering department employs 15 people full-time: 12 technicians, one clinical engineer, one director, and an administrative assistant. Until recently, the technician categories were limited, but a desire to provide the staff with new opportunities led to the addition of a new category more in line with other shops that have clear career paths. The hierarchy now includes repair assistant, BMET 1, BMET 2, and BMET 3.

The BMET 3 position incorporates additional responsibilities that include mentoring and project management. “We wanted to find a way to accommodate those folks that were interested in leadership and taking on more tasks,” Dudley says.

The BMET 3 title requires 8 years of experience and an AAMI certification, or a 4-year degree in biomedical education and 2 years of experience. “We have also asked that we be able to consistently see some effort toward certification,” Dudley says. BMET 2 candidates must have 2 years of experience or a bachelor’s degree and 1 year of experience.

Anthony Phoenix, a BMET 3, works on the setup and configuration of the anesthesia machine patient monitoring system.

The department asked eligible staff members if they would be interested in the new role. Half said yes. “What inspired me about the BMET 3 position was the fact that it had leadership responsibilities in regard to project management and department initiatives,” says Anthony Phoenix, a BMET 3 at Wishard. Phoenix feels he has already benefited in his new role, becoming more familiar with regulatory requirements and their influence on the hospital’s standards and procedures.

Serving With House Calls

However, no matter what the level of a Wishard biomed technician, or if he specializes in a specific area, such as anesthesia machines, he must serve his time on house calls.

“On a particular day, [the house call individual] is responsible for all repair calls, whether emergency or routine,” Dudley says. Emergency calls refer to safety or life-support issues; routine requests have less urgent needs. Every house call must receive a response that day; emergency calls should be addressed within minutes. The repair is not required to be completed that day, but the clinician should receive a response and steps should be taken to remedy the issue (eg, parts ordered or vendor called).

The workload can vary, ranging from one call one day to 21 another, according to Demetrius Dillard, a BMET 3 at Wishard. And the call can come from anywhere in the hospital. In general, whoever is on house call duty is exposed to a wide variety of issues, which keeps the generalist skills of everyone on the team honed.

Joe Taylor, a clinical engineer and a CBET, is the educator for the department.

“Everybody has at least a basic knowledge of the devices,” Dillard says. “That way, in the event that you’re out in a department and a clinician asks you a question, you can start them on the right path and make them feel comfortable that somebody is taking care of their equipment.”

Caring for Equipment

When not on house calls, or enjoying a low-call day, the technicians work on projects or preventive maintenance (PM). PMs are assigned by specialty, interest, and workload. The team divides the inventory (roughly 18,600 devices) among “core groups.” Once a year (or on the fly, if necessary, Dudley notes), the technicians scan the inventory for equipment they might be interested in learning more about through service and maintenance. If devices in that discipline are unclaimed, they can ask to take those on.

“The hospital may have 30 fetal monitors, but a technician has responsibility for five of them because they want to learn more about fetal monitoring,” Dudley says. If a technician wants something new, he can ask the team if anyone would be interested in taking the equipment on.

“Once the other person is trained, we can just go into our database and reassign the core group to the new guy,” Phoenix says.

As preventive work orders are generated by the clinical equipment management system, those devices that are part of a technician’s core group are assigned to that technician. Unclaimed items, such as suction regulators and sterilizers, are then divided among the team, evening out workloads.

Advocating Risk Management

In general, the team approaches PM with resources in mind. Rather than simply follow manufacturer or regulatory guidelines, the team completes a risk analysis for each device to determine a safe but smart service schedule. The program analyzes equipment function (life support, diagnostic, analytical, etc); clinical applications, involving risk estimations related to the impact of failure (eg, misdiagnosis, death, etc); and a score based on whether the manufacturer maintenance requirement is extensive, average, or minimal.

Mohammed ALAmeer, an IUPUI biomed student, works on his senior project at Wishard Health Services.

“Then we add those numbers together and assign a PM interval based on that,” says Joe Taylor, CBET, the clinical engineer on the Wishard medical engineering team. More critical PMs frequently have semi-annual schedules, though the facility has obtained a waiver from the Indiana State Board of Health to extend intervals for equipment with a proven history.

“For example, we’ve extended the interval on vital signs monitors from 1 year to 2 years based on the review of their history,” Taylor says. “In the case of the devices we were checking, we did not find reasons to make an intervention.”

To help with future investigations of this type, the team now documents whether any repairs are completed during a PM. “This will make it easier for us to track systems that don’t have issues and those that do, so we can then make our adjustments accordingly,” Taylor says.

Serving Two Sites

Like many shops, the Wishard team also tracks support status for equipment in its computer equipment management system, a piece of data that has been useful in equipment planning, particularly now that the hospital is moving. Expected to open in December 2013, the new facility—supported by a $40-million-dollar gift from Sidney and Lois Eskenazi and situated across the current parking lot—will come equipped with new devices where possible.

“Some of our [current] equipment needs to be replaced, just as it would if we weren’t moving,” Dudley says. “So as we look at what we’re replacing, we have to ask if it will fit the current need and the need at the new place.” If it does fit both needs, then justification is easy, but if it will not work in the new facility, then there may need to be a workaround.

Lipshed Ndebele, a work-study student, inspects the connections on an infant warmer.

The Wishard team, however, can handle it. “Because of the nature of our institution, we are always strapped for funds,” Taylor says. Planning purchases is difficult when financing is not secured. When a manufacturer announces that a device will no longer be supported, the Wishard team creates a plan to deal with the ultimate failure of the equipment. “And we begin to put a team together to discuss what might replace it,” Taylor says.

The department currently has a number of projects under way, the largest of which is the move to the new hospital. To make the process efficient, Wishard has organized clinical transition meetings, which largely focus on workflow in the facility. “Understanding the workflow helps us understand what equipment is needed where. So we can move away from old stigmas to try and help the clinician better care for the patient,” Dudley says.

When considering capital purchases, the team uses a process that involves research, sales presentations, product comparisons (using databases such as ECRI Institute’s tool), and multidisciplinary committee analysis of pros and cons. “People have a chance to give their opinion,” Taylor says. “In the best-case scenario, clinical staff is able to complete written evaluations.”

Advocating for New Skills

The Wishard biomed department, like many others, often finds itself in multidisciplinary situations. More frequently, collaboration with IT is required to complete a project. As more systems are networked, their input and expertise is often necessary, but biomeds can sometimes get lost in the IT universe. “In my 19 years here, the IT department has expanded, and it can be a challenge to find the right person with whom to work,” Taylor says.

BMET 3 Demetrius Dillard performs routine maintenance on a ventilator.

The addition of a clinical apps director to the IT department has begun to facilitate this process. “When we have a project coming, we ask [the clinical apps director] who we should work with,” Dudley says. She also helps to define boundaries for working together. For instance, “when we’re troubleshooting an issue and can confirm data flow to a specific server, that’s the point we turn it over to IT,” Dudley says.

Even after the responsibility for the task has been turned over, however, biomeds maintain ownership, confirming with the customer that the repair has been made. “We don’t want our customers to call us, then have to call IT, then have to call us again,” Dudley says. “That is no good. Typically, they call us first, and we track that repair all the way back to customer satisfaction.”

Of course, the biomed team would like to be able to take care of some of the IT-related issues in-department, in part for timely response and in part due to professional pride. The group as a whole is continuously acquiring new skills, and individual technicians have completed IT certification programs. The entire biomed department participated in an IT study group to familiarize itself with general topics in the discipline, such as servers and data transfer.

“We try to educate ourselves so we can do a lot of projects on our own—or at least be able to sit at the table and communicate with IT when we do have to work with them,” Dillard says. As the biomed team proves its capabilities to itself and IT, service and maintenance become easier and more efficient. “It’s a growing partnership, and we’re setting the groundwork now for a favorable relationship with them in the new hospital,” Dudley says.

Teaching Future Biomeds

Martin Teasley, repair assistant, works on a failed surgery table.

The team is also setting the groundwork for future clinical/biomedical engineers with a strong level of participation in educational endeavors. Wishard is associated with Indiana University-Purdue University Indianapolis (IUPUI) and accepts its students as interns, residents, work-study employees, and volunteers. The medical engineering department is currently hosting one student completing his senior project, one student doing a practicum, another on work-study, and a fourth volunteering.

The parameters for each position vary, ranging from education-focused (such as with the practicum student) to employee-focused (as for the work-study student). The student may work with a different biomed every day to achieve exposure to specific equipment. “We like to put them in real-world situations and show them what a day in the life of a biomed professional actually is,” Dillard says.

Two key messages that get stressed include patient safety and solid documentation. “I try to show the student how important it is to get data entry done and done correctly,” Phoenix says. “The sooner you do your paperwork, the fresher the information is in your mind and the more accurate it will be.”

Everyone in the department participates. Hosting the students can be time-consuming: “We’re watching, we’re showing, we’re demonstrating, we’re backing up, we’re explaining, and we’re answering questions,” Dudley says. But Dillard notes the extra set of hands can sometimes help to speed things up. And the effort is rewarding.

“We’re preparing people for a career, and there is payback,” Dudley says. The department has hired a number of the students as full-time staff. Dillard is one such employee, having transitioned to full-time work from an internship. Now he’s educating others, not only through his mentorship role but also through an in-house certification study group he has organized.

The 12-person group (Phoenix is also a member) meets regularly to review and exchange exam information. Dillard, who is president of the Indiana Biomedical Society, worked with the organization to make the study group open to anyone in the area. Much of the material has been supplied through another collaboration, this one with the Colorado Association of Biomedical Equipment Technicians, or CABMET. The result has been a helpful tool in preparing for the certification exam.

“The study group gives you an environment where you can explore ideas, discuss topics you don’t understand well, and strengthen your weak points,” Dillard says. He advocates certification as a way to increase the professionalism of the biomed field and has been happy to organize the study group to help others with the opportunity.

The effort epitomizes the Wishard mission to advocate, care, teach, and serve, or ACTS, and is just another example of how the mission is reflected in many of the biomed team’s ACTS. As the department moves forward and transitions into Eskenazi Health, it will continue to focus on that mission—and do so for another 150 years.

Renee Diiulio is a contributing writer for 24×7. For more information, contact .